In Eileen Fisher’s new collection, there’s a wool cashmere sweater with a chic funnel neck and boxy silhouette. It’s plush, soft texture reflects the high quality the brand is known for (and its $348 price tag). You’d never know that it was made from well-worn, hole-ridden sweaters Eileen Fisher customers sent back in.

For decades, we’ve had the technology to recycle aluminum, paper, and plastics. But we haven’t had the systems to do the same with clothing. As a result, only 1% of new clothes on the market are made from old clothes; the other 99% are made from new fibers, which requires extracting raw materials from the earth. But if the fashion industry is going to curb its enormous environmental footprint, we need to invest in textile-to-textile recycling.

Eileen Fisher believes we’re closer than ever to achieving this reality. For years, the company has been buying recycled fibers from the small number of mills that source old garments from around the world to recycle the wool and cotton fibers within them. But this sweater is special. It is made entirely of old Eileen Fisher sweaters. It is a beautiful illustration of how fashion can transition to a circular system, where old clothes are perpetually recycled into new ones, and we no longer rely on raw materials.

The Art of Wool Recycling

Inka Apter, the brand’s director of material sustainability and integrity, points out people have used traditional methods to recycle wool for centuries. For much of human history, clothes were very valuable because they required a lot of labor to create. Wool and cashmere were precious materials, so when garments reached the end of their long lives, craftspeople would break down the yarns then respin them into new fibers.

All of this has changed over the past 150 years, as the modern, industrialized clothing industry has found ways to make clothes quickly, at scale. Consumers have started to see clothes as disposable. This has been particularly true since the advent of synthetic fibers like polyester and nylon, which are made cheaply from fossil fuels. But while clothing is cheaper than ever, its impact on the planet is enormous, generating up to 8.6% of global climate emissions.

Recycled fibers have a significantly lower impact on the planet. Using recycled wool, for instance, means you’re avoiding the emissions around raising sheep and processing the wool into fiber. As a result, recycled wool saves about 60% of the impacts of virgin wool.

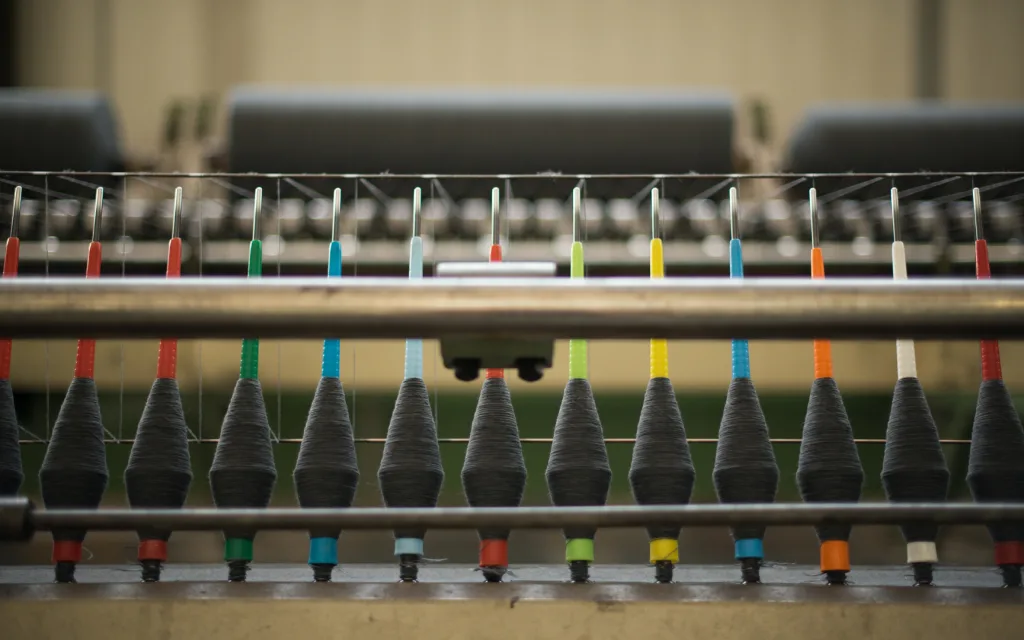

There are now a few mills around the world that specialize in recycling wool and cashmere at scale. These mill source old fabrics, known as feedstock, everywhere from donation bins to overstock garments. For years, Eileen Fisher has been sourcing recycled wool from a mill in Italy called Reverso known for producing high-quality recycled fibers. But over the past few years, the brand’s director of circular design, Carmen Gama, and Apter have been on a mission to create sweaters at this mill using old Eileen Fisher garments. “This would be closing the loop, and creating an entirely circular sweater,” Gama.

A Fully Circular Sweater

While we have municipal recycling bins to collect paper and aluminum, there isn’t the same infrastructure for collecting clothing. Eileen Fisher has had a take-back program for decades, inviting its customers to bring back clothes, either in store or by mailing them in in exchange for a $5 gift voucher for each garment.

The company is known for its sustainable practices. Its customers appear to be particularly eco-friendly and are willing to send back old clothes, even if it means paying out of pocket for shipping. Every month, the company receives more than 25,000 garments. “Sometimes we get boxes where they’ve paid more for shipping compared to what they’re getting from a coupon,” she says.

One reason that fabric recycling hasn’t been able to scale is that many recyclers cannot process mixed-material garments. They can only process clothes that are made from 100% wool or cashmere. This is a problem because the vast majority of sweaters on the market today are either made entirely of cheap synthetic fibers, like polyester, or are made from wool mixed with polyester, which brings down the overall cost of the sweater.

So Eileen Fisher does the work of sorting through the clothes that customers have sent in, separating out the ones that are made from single fibers. The company sent two containers of these old sweaters to the Italian mill to be transformed into new fibers. Every stage of the process was tracked, to ensure the fibers ended up in the final product.

Going forward, Gama says that circularity will inform the design process. Eileen Fisher already makes many of its sweaters out of a single fiber, without blending them with synthetic fibers. But it will push for more mono-materials because it makes the recycling process so much easier. “It just shows that to create a circular system, you really need to be thinking about the design process from the beginning,” says Gama. “The purer the fabrics, the easier they are to recycle.”

Many Eileen Fisher customers were thrilled to see the recycled wool cashmere sweater on the website. They could imagine the sweaters they had worn and sent back transformed into this beautiful new product. And, in many ways, that was the whole point of this particular project. “It would have been far easier to just buy recycled wool fibers from this mill,” Gama says. “It’s much harder to collect our own sweaters, then track them through the system.” But she points out that customers are more motivated to send old clothes back when they can see the results of their efforts. “It’s the most powerful way to inspire them to recycle,” she says.

And there are more circular sweaters to come. Eileen Fisher already has two more containers of sweaters ready to be shipped to the mill and transformed into new sweaters.