Until recently, if you threw away an old mattress in Amsterdam, it would likely end up in an incinerator—the same way that most of the 15 million-plus mattresses thrown out in the U.S. each year end up in landfills.

Now, however, around half of Dutch mattresses are recycled, and that number is growing. Some of the material is starting to be used in new mattresses, sofas, and other furniture by manufacturers like IKEA.

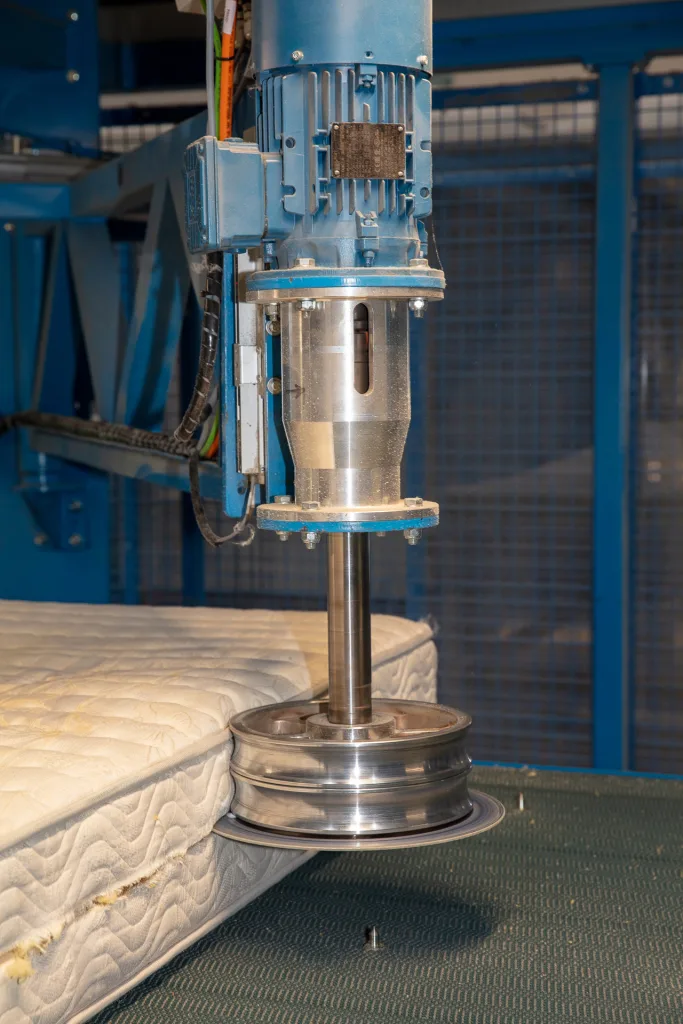

In one facility near Amsterdam, a company called RetourMatras uses automated equipment to dismantle old beds, beginning with a machine called a peeler that cuts off the mattress cover so the fabric can be recycled. Then the core is separated into materials like polyurethane foam, latex foam, and metal springs, depending on what’s inside a particular product. More than 80% of a typical mattress can be recycled. In another corner of the facility, the company has pioneered a process to turn polyurethane foam into the chemical building blocks for making new foam that can be used in furniture.

In the past, shredded foam could only be “downcycled” into a lower-quality material for products like carpet backing. Now, if you buy an Extorp sofa or Poäng chair from IKEA in Europe—or a new mattress—it will likely contain foam partially made with chemicals that RetourMatras recycled from old mattresses.

The investment arm of Ingka Group, IKEA’s largest retailer, first invested in the recycling startup in 2019 to help it scale up. The aim was to help with IKEA’s own circularity goals. “We would like to recycle as many mattresses as IKEA puts on the market globally,” says Alberic Pater, who manages business development at Ingka Investments. (Last year, the company sold more than 11 million mattresses.)

At the time of the first investment, there was almost no recycling capacity in the region, Pater says. “Incineration or landfill was still commonplace, because the cost was far cheaper than recycling,” he says. Cost is still a challenge, though RetourMatras says that automation is helping—along with the fact that the company can now produce higher-quality materials for use in new furniture.

The recycling company now has three facilities in the Netherlands, along with three facilities in the U.K. and one in France. In total, it has the capacity to recycle 2.5 million mattresses in a year; last year, it handled 1.6 million. So far, only the location outside of Amsterdam has the new tech. But another new investment from IKEA will help the startup grow. This month, the furniture giant announced that it planned to invest more than $1 billion in recycling infrastructure, including an unspecified amount in RetourMatras. (The recycler hasn’t yet announced any plans to expand to the U.S., and so far, there aren’t any other American recycling companies with the same type of foam-to-foam recycling technology.)

At the same time, IKEA’s product designers are working on making mattresses more recyclable. For example, many of its mattresses now have covers made from 100% recycled polyester, which can be recycled again. The covers also have zippers, so they’re easier to remove.

“It’s extremely easy just to unzip the cover, take out the foam, and let the cover go in a different recycling stream,” says Johan Kroon, a product developer for Inter IKEA. (Because they’re removable and washable, it also makes it more likely that consumers will keep the mattresses longer, which can cut the environmental footprint of the product even more.) The company’s product design team is working on multiple projects related to mattress recyclability, including making it easier to separate the materials inside.

Other companies are also innovating in the space. Royal Auping, a Dutch company that has made mattresses since 1890, designed a fully circular mattress in 2020. Called Evolve, it’s made from only two materials—PET, the material used in plastic water bottles—and steel springs. A specially-designed adhesive makes it possible to separate the materials with heat instead of energy-intensive shredding. PET is also easier to recycle than foam. The design has fewer than half of the components of a typical mattress, but is as comfortable, the company says, with better ventilation than a foam mattress.

RetourMatras says that mattress brands can tour its facilities to better understand how to design for recyclability. It will take time to see the benefits. “We’re dismantling mattresses from 10 years ago,” says Chico van Hemert, managing director at RetourMatras. “If we change something now, we’ll benefit in 10 years.”

Meanwhile, IKEA’s product developers are also figuring out how to use the new recycled foam. Right now, it only makes up a small percentage of the total material in the company’s products; one IKEA mattress sold in the Netherlands, for example, uses 10% recycled polyol, the main building block for making foam. That percentage can increase as the supply of recycled material keeps growing and costs come down.

“The biggest challenge is to get more mattresses,” says Pater. IKEA collects old mattresses at its stores, but governments need the right policies to collect mattresses at a large scale. Several European countries now have “extended producer responsibility” laws that require mattress retailers to figure out how to get old mattresses back for recycling. The U.S. lags behind, but four states also have similar laws. “We need more markets, more countries, to implement the right legislation,” he says.